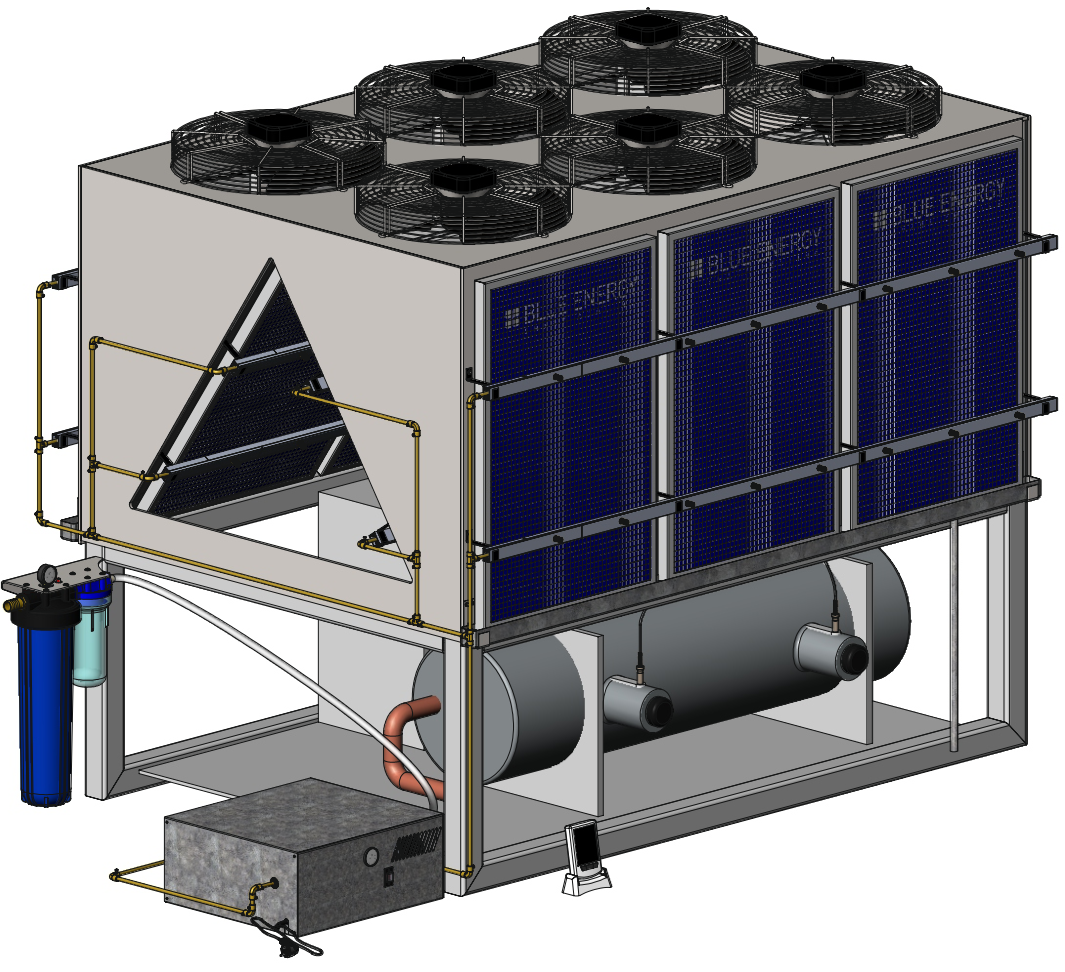

To this day, PreCooling plays an important role in improving the efficiency of cooling and air conditioning systems.

The Pre Cooling system is designed to maximize efficiency, easy to handle, easy to install, takes little space and is lightweight.

The primary task of PreCooling is to drastically reduce the direct air temperature to the cooling or air conditioning condensers. Our task is not to make them wet.

PreCooling system is adaptable to any type of air conditioning and cooling equipment that cools itself down by air.

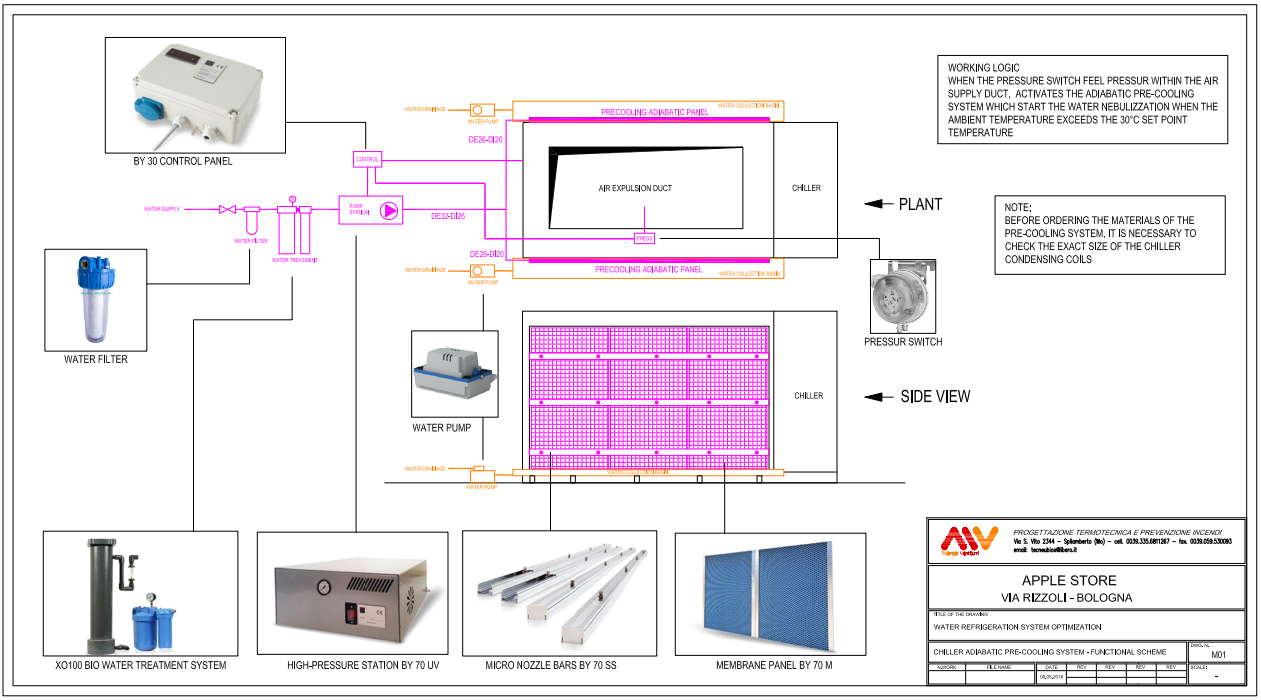

How PreCooling works

Water is supplied to the water preparation unit.

The water supply is connected to the block of water preparation in biochemistry and further is directed towards filtering water mechanical particles

The submerged water must have a minimum pressure of 3 bar and as clean as possible, although the PreCoolig system provides a water treatment unit with mechanical particle filtering.

Biochemical block – protects condensor from liming, corrosion and other forms of oxidation.This is one of the main stages of water preparation. As it is known in the water there are several chemical compounds including lime molasses. With a help of composition of biochemistry, it modifies the structure of lime molecule in the water. This means that the lime molecules will no longer stick to the surfaces, but will run off with the sprayed water. Biochemistry contains a number of components that protect the condensor against corrosion and other forms of oxidation, which means that the condensor will be clean and able to perform the technical characteristics of the cooling and air conditioning equipment manufacturer.

After the treatment of biochemistry, water is fed to the water mechanical debris purification filter. At this stage, mechanics and debris particles are removed from the water so that the maximum amount of clean water is delivered to the nozzle system and the operation of the PreCoolig system is at the highest level of efficiency. The water filter is equipped with a pressure gauge that accurately displays the pressure of the incoming water.

High pressure equipment prepares water under pressure from 70 bar to 140 bar. Water consumption depends on the workload. The maximum water consumption at full working load is 6L / min. Average daily consumption of water can range from 1m3 to 3m3.

High pressure pump is an IP 65 type equipped with valves, pressure indicator, power switch and engine.Without this all-in-one ultraviolet light (UV) is built into the pump, helping to kill legionella bacteria in the water. The high pressure operation is controlled by the control unit. The high-pressure pump is equipped with a separate on / off button which provides extra security.

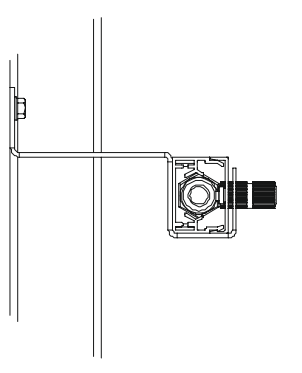

Water preparation block connection scheme with high pressure equipment

The technical task of the control unit is to control the operation of the high-pressure pump with its built-in sensors and other signal reading devices.

- Control mechanisms:

- Climate temperature sensor. The air temperature is set in the control panel and the setpoint pump switches on or off when the set temperature value is reached.

- Arriving signal for air cooling or freezing equipment. This means that the PreCooling system will be able to start working if the cooling or air conditioning unit will be in operating mode.

- Moisture sensor

PreCooling works based on water spraying, which means that if the climate is saturated with more than 90% humidity, the control unit will shut down the system. This control function is provided at the time of rainfall in the atmosphere. - Pressure sensor

The function of the pressure sensor is to protect the PreCooling system from water leakage if the proper technical operating rules are not observed or in the event of an accident. - Water supply sensor

If the water supply is interrupted or if the inlet pressure is lower than 3Bar, the high pressure pump switches off.

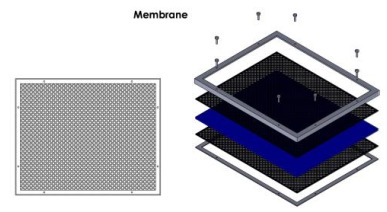

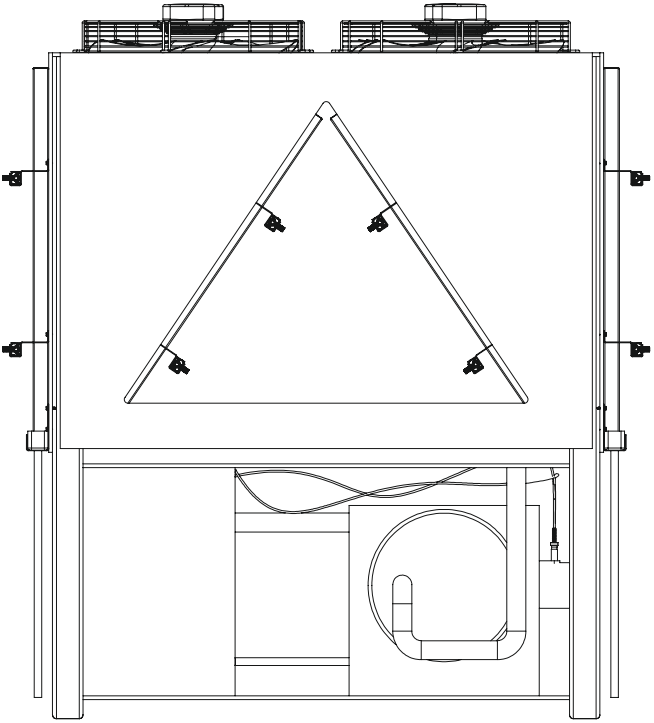

Membrane is made of custom made polyurethane material and is included in aluminum frame.

Membranes functions:

- Protect the condensers of cooling or air conditioning units from direct sunlight. As we know, a cooling or air conditioning unit is basically built on the roofs or often in places where they are exposed to direct sunlight , as a result, the condensers are heated and the performance is reduced. The membranes are built around the condenser and thus shades the shading effect and does not overload the condenser.

- Membranes collect atmospheric dust without passing them through the condenser. This means that condensers are protected from atmospheric dust, they will always be able to perform the technical specifications specified by the manufacturer.Part of the accumulated atmospheric dust from the membrane runs down with the sprayed water.

- Membranes hold water through.

The PreCooling system is based on cooling the incoming air temperature so that the air passing through the membrane is as dry as possible. This means that the sprayed water from the nozzle system enters the membrane and is detected with atmospheric dust, but the condensers are clean, dry and protected from any kind of climate or water exposure.

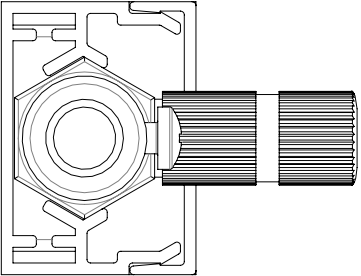

The components of the nozzle system are made of stainless steel and are included in an anodized aluminum panels to ensure a clever operation and protect against any damage.

Anodized nozzle panels are custom-made to protect the nozzle lines from mechanical impact.

Water is sprayed through nozzles with 5micr small water flakes,which means that by spraying water it instantly absorbes the particles of warm air and thus the energy is exchanged,resulting in lowering the temperature in the moment and that is called adiabatic process in the nature. This process occurs in nature near waterfalls, during rain or in other places where microscopic particles of water enter the air.

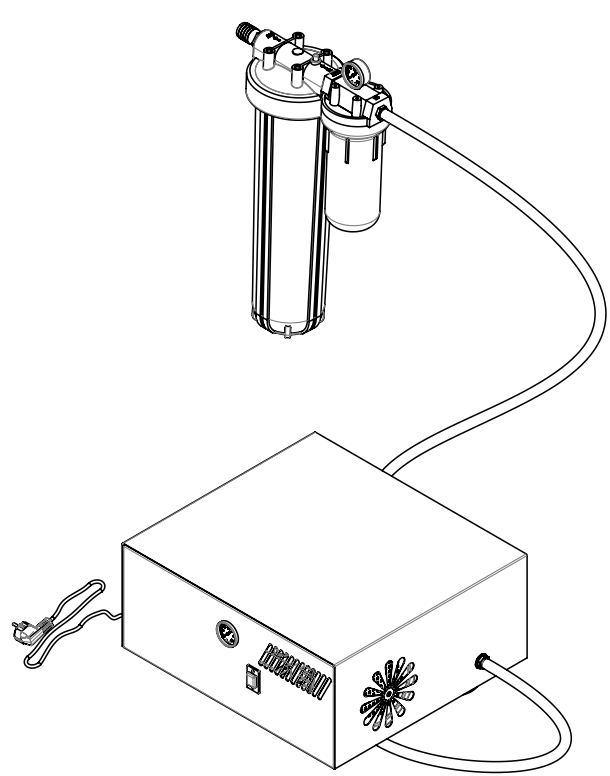

BIO water treatment systems

BIO water treatment systems

Water filter

Water filter

High pressure equipment

High pressure equipment

Control unit

Control unit

Membrane

Membrane

Nozzle panels

Nozzle panels

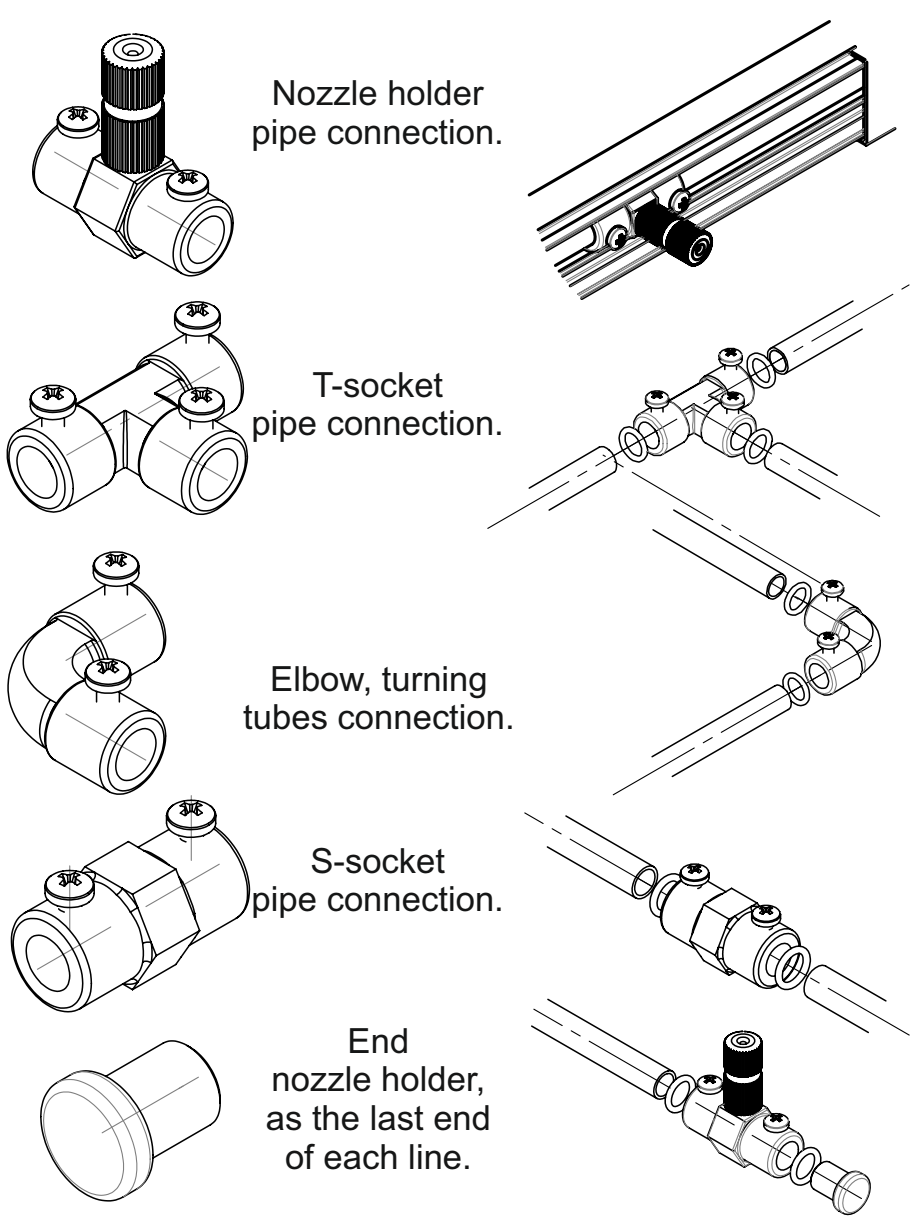

Nozzle panel scheme

Nozzle panel scheme

Connection elements in the nozzle system

Connection elements in the nozzle system