Economy of electricity consumption up to 41%,increase cooling power efficiency up to 37%, Adiabatic panels precooling for chillers and dry coolers.

Energy efficiency up to 41% Increasing cooling power efficiency up to 37% The operating time for chiller and dry cooler is longer The condenser is protected from corrosion. Condenser protection from atmospheric pollution Is provided maximum purity for condensors from atmospheric pollution. There is no Legionella

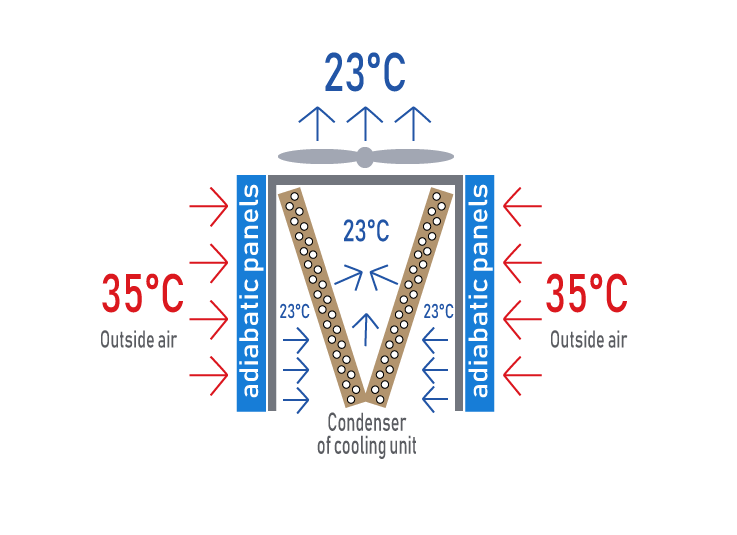

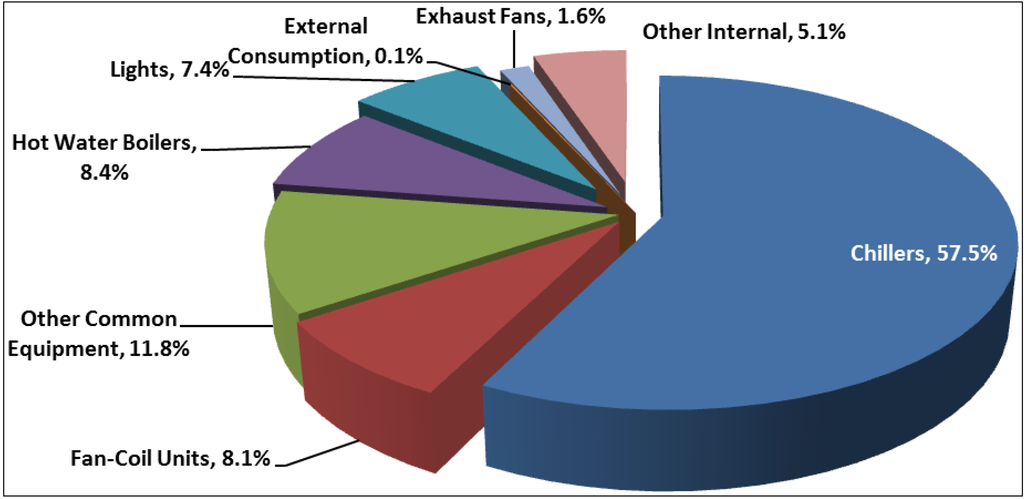

Using PreCooling technology can significantly reduce air conditioning and cooling unit inlet air temperature. As a result, it is possible to consume a lot less power to cool air up to a pre-determined temperature. Reduction of the power consumption is very important, because the chilling and conditioning equipment consumes a significant portion of all energy consumption of the building - up to 60%.

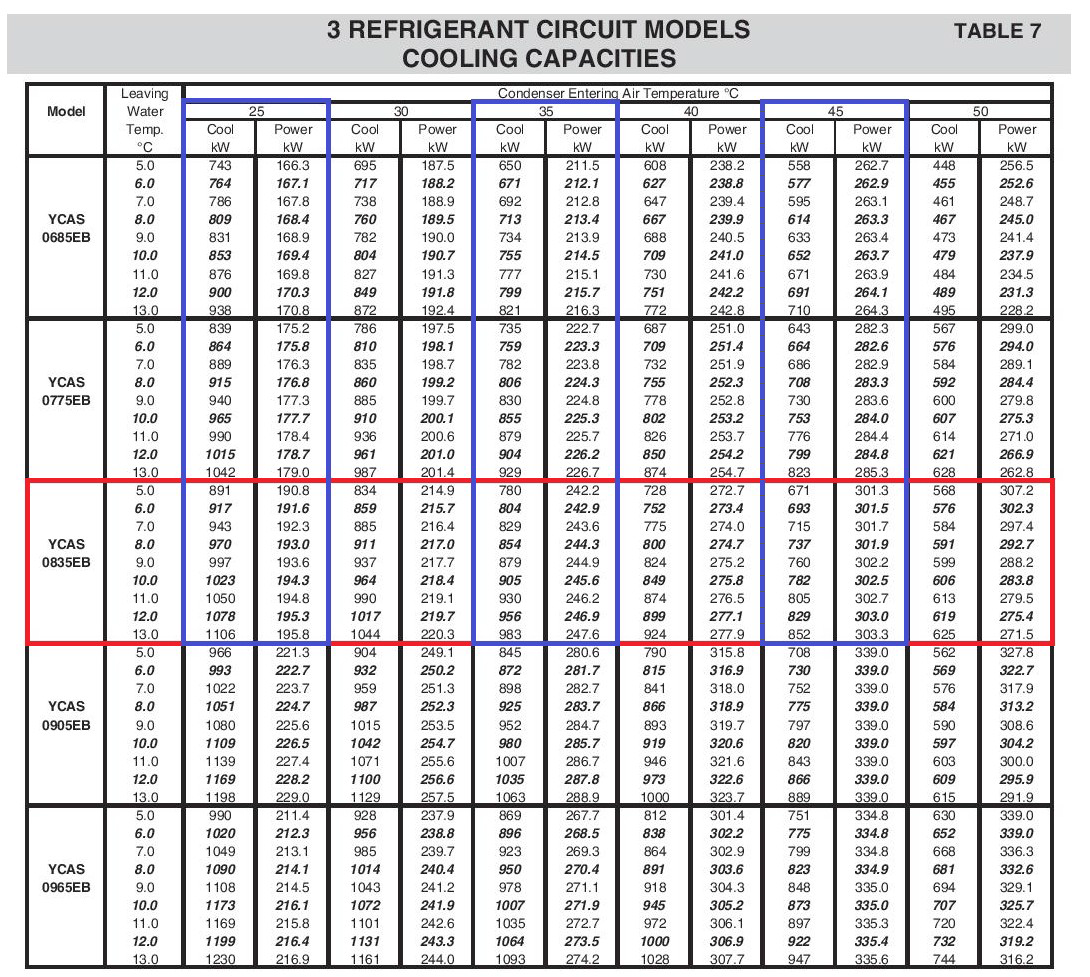

Each manufacturer of the air-conditioning and cooling equipment provides information about the electricity consumption of the equipment. This information is available in the form of a standardized table showing electricity consumption for cooling the inlet air at the determined external ambient air temperature. However, regardless of the manufacturer, there is a correlation - the higher the outside air temperature, the higher capacity cooling plant is needed and consequently more power is consumed.

SUMO 交易所

The table shows the electricity consumption and the cooling capacity in the cooling unit.

Let's take YORK YCAS 0835EB as an example

At outdoor temperature 25째C

Cool kW 1023

Power kW 194.3

At outdoor temperature 35째C

Cool kW 905

Power kW 245,6

At outdoor temperature 45째C

Cool kW 782

Power kW 302,5

GAMEUNITS 交易所

SWASH TOKEN APP

SSE EXCHANGE

SB GROUP 交易所

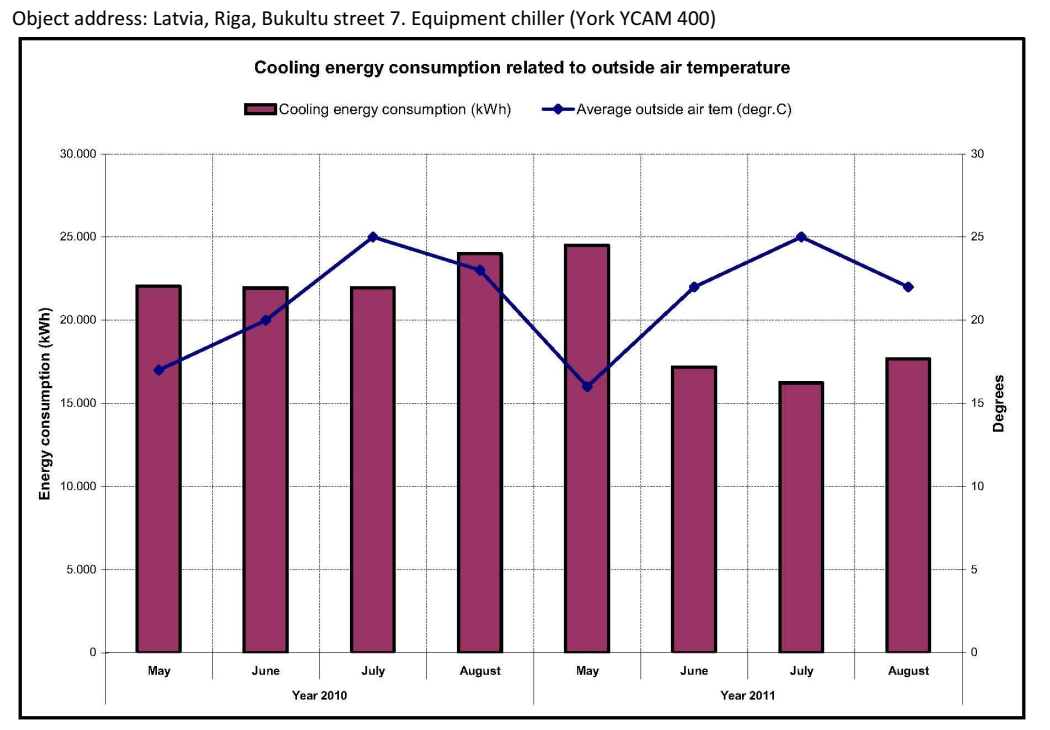

The graph shows a comparison of electricity consumption and cooling capacity for the summer months of 2010 and 2011