PreCooling offers innovative solutions to increase the efficiency of the process of adiabatic air-cooling systems - PreCooling. In addition to the increase of efficiency of the cooling capacity, this technology allows to significantly save the electrical energy consumed during operation of the cooling and air conditioning equipment and to ensure longer service life of the equipment as well.

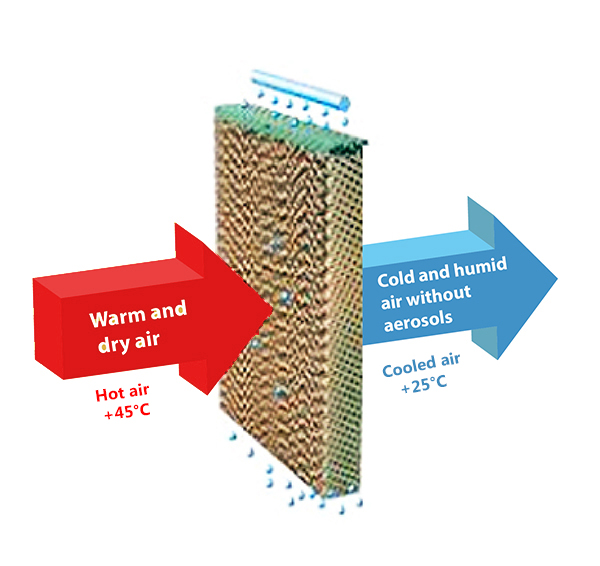

PreCooling Panel is installed before air conditioning and refrigeration equipment condenser for the cooling system. By use of the special technology of PreCooling, the system sprays fine mist of water creating a fog effect, which causes evaporation in the air drastically reducing the temperature of the inlet air in the condenser in an adiabatic process.

In contact with warm air a certain amount of water evapora tes and as a result of the energy exchange the air temperature drops dramatically (approximately 10-20 ° C), which allows consumtion of less electric energy to provide the required temperature. To further lower the intake of air temperature, the special membranes are used, which block the effects of the direct sunlight on the condenser and keep it clean. The total electricity savings can reach up to 30%.

In contact with warm air a certain amount of water evapora tes and as a result of the energy exchange the air temperature drops dramatically (approximately 10-20 ° C), which allows consumtion of less electric energy to provide the required temperature. To further lower the intake of air temperature, the special membranes are used, which block the effects of the direct sunlight on the condenser and keep it clean. The total electricity savings can reach up to 30%.

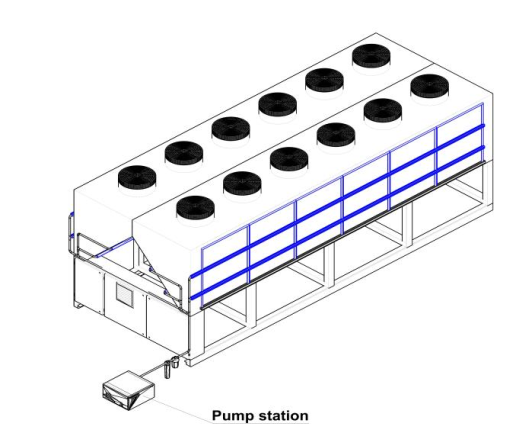

The Adiabatic systems PreCooling consists of the following parts:

- Pump unit

- Control panel to enable automatic operation of the system

- Water treatment system

- Panels with sunlight reflecting and inlet air filtration membranes

- Water-spray nozzle system

- PreCoolin system is equipped with a UV (Ultra Violet) lamps that eliminate the formation of Legionella bacteria and other bacteria in water

Pump unit

High-pressure PreCooling equipment is designed to deliver high pressure from 70 to 140 bar, pass through itself at 3 - 43 l / min and be maximum economical. The equipment is an IP type equipped with valves, pressure indicator, power switch and engine. In this way, the equipment is able to provide the necessary pressure in the system.

For each project, the equipment of the respective capacity is selected, which supplies prepared water to the nozzle system built at the condenser. In this way, water is sprayed through the nozzle system and a mist effect of 5 microns of water particles is created ,by instantaneous evaporation of air, the incoming air temperature in the condenser is drastically reduced.

Control panel to enable automatic operation of the system

High Quality Performance Control Unit is an IP 65 class equipped with protection and a built-in screen that controls the PreCooling process. With the help of the control unit, you can set the operating cycle of the PreCooling high pressure equipment, which depends on the outdoor air temperature and the cooling cycle.

The relays built into the control unit reads the outdoor air temperature, humidity, air conditioning or freezing equipments trigger signal.

The PreCoolig device is only switched on when there are all these signals in the control unit.

To provide a complete control cycle, the control unit is equipped with a protection system against overheating and water pressure loss in the system.

The control unit control program is designed to make the PreCooling system as economical as possible and to consume as little water as possible.

Water treatment system

The water preparation plays a major role in the process and consists of 3 components:

- Ultraviolet radiation lamps (UV lamps)

- BIO water recycling filter

- Water Descaling equipment

- Mechanical Particle Purification Filter

- Legionella bacteria and other bacteria that can adversely affect human health are killed in the incoming water that comes with the UV lamp.

- The BIO water filter contains patented granules and this water preparation cycle is important, because the structure of the lime molecule is changed. This means that the lime microparticles in the water no longer stick to the surfaces, but are washed with water. By spraying water through micro nozzles, they are not clogged and lime deposits do not come into contact with the condenser surface. The BIO filtration process protects the metal surface from corrosion and other oxidation.

- The decalcification of water is based on a new generation of equipment, with which help the lime on metal surfaces is neutralized by water.

- The mechanical particle filter collects debris,that is in the water.

With such a water preperation is guaranteed high water quality, which provides a clean surface without corrosion and other oxidation to the metal surfaces of condensers in the cooling or air conditioning system.

Panels with sunlight reflecting and inlet air filtration membranes

The Membrane panel is made of high-grade polyurethane material, which is embedded in the frame. The membrane panel is designed to be as simple as possible, long-lasting and highly efficient.

The membrane is attached to the cooling or conditioning device on the condenser surface covering the entire plane. The main functions of the membrane is to cover the surface of the condenser by shielding it from direct sunlight, atmospheric dust, holding the sprayed water and being wet to create maximum efficiency for lowering the air temperature.

Sprayed water comes into the membrane from the nozzle system, so that the condensers for cooling and conditioning equipment are always dry and clean.

Water-spray nozzle system

PreCooling Nozzle System is made of stainless steel components built into the aluminum housing. The housing is attached to the frame of the cooling or air conditioning unit with custom made and adapted fasteners before the membrane, which includes fast, simple construction.

For maximum effect with minimal water consumption, a calculation is made based on the number of nozzles required. This ensures maximum surface treatment with sprayed water microparticles, resulting in a drastic reduction in air temperature. Evaporation of water results in an energy exchange between water and air - an adiabatic process.

EASY AND ECONOMICAL MAINTENANCE

Maintenance of the PreCooling system should be carried out regularly

BIO chemical replacement

Water mechanical and other debris filter replacement.

Membrane’s cleaning from atmospheric pollution.

Maintenance can be done by a professional service company or a trained employee.

- Maintenance of the PreCooling system must be carried out regularly. As the system has a water filter block, it should be regularly monitored. The water debris filter has to be changed depending on the water purity, which may be monthly, less frequent, or even more frequent.

- BIO filter water granules should be changed once in 90 days.

As the membranes collect atmospheric dust, they need to be cleaned depending on the climate, it may also be monthly or less frequent.